Intro:MB220 is a kind of halogen free environmentally friendly flame retardant masterbatch with N and P, non-APP based system. MB220 has higher thermal stability and higher decomposition

Color:White

Intro:MB220 is a kind of halogen free environmentally friendly flame retardant masterbatch with N and P, non-APP based system. MB220 has higher thermal stability and higher decomposition

Color:White

86-532-80698192

Features

MB220 is a kind of halogen free environmentally friendly flame retardant masterbatch with N and P, non-APP based system. MB220 has higher thermal stability and higher decomposition temperature. Besides, it can easily get processed. PP with MB220 can pass the tests of UL94 V-0 (1.5mm), 70℃×168hrs water-immersion (UL746C); besides, it can also pass the tests of GWIT 750℃ and GWFI 960℃. And it is free from the restrictions of RoHs Directive 2011/65/EU approved by the EU and the Council. Glass fiber reinforced PP with MB220 can reach UL94 V-0 (1.5mm) as well. The products with MB220 have the characteristics as low density, lower smoke generation and less mold corrosion. Polyolefin with MB220 will not have the phenomenon of water-sliding surface during the process of extrusion, and sieves can be added during the process.

Reference dosage

PP/PE/EVA | PP+30%GF | TPE(PP+SEBS) | |

MB220% | ≥30% | ≥35% | ≥55% |

Flame Retardancy UL94 | V-0 (1.5mm) | V-0 (1.5mm) | V-0(3.0mm) |

NOTES:

1. Because of the decomposition temperature of MB220 in nitrogen is 270℃, the processing temperature of twin screw can be adjusted higher accordingly, and a sieve can be put on the head of machine. Maintaining vacuum of the twin screw during the processing is also needed.

2.The substances which affect flame retardant performance: phthalocyanine green that contains Cl-1 toner will make the flame retardant loss effect. If the dosage of carbon black is higher than 0.5%, the flame retardant performance will be weakened.

Patents and regulations

Comply with RoHS, REACH, etc

Packaging and storage

25kg per bag, using paper bags with PE inner. Products should be sealed storage, stored in a dry and cool place to avoid dust

APPLICATION EXAMPLES

1.FORMULA:

MATERIAL | FORMULA D | |||

HOMOPOLYMERIZED PP | 56.3 | 56.3 | 33.8 | 69.3 |

GLASS FIBER BF970M0 | 10 | 20 | 30 | 0 |

MB220 | 33 | 33 | 35 | 30 |

POE | 0 | 0 | 0.5 | 0 |

LUBRICANT EBS | 0.3 | 0.3 | 0.3 | 0.3 |

ANTIOXIDANT AGENT B215 | 0.2 | 0.2 | 0.2 | 0.2 |

ANTI-DRIPPING AGENT 449 | 0.2 | 0.2 | 0.2 | 0.2 |

2, PROCESS TECHNOLOGY:

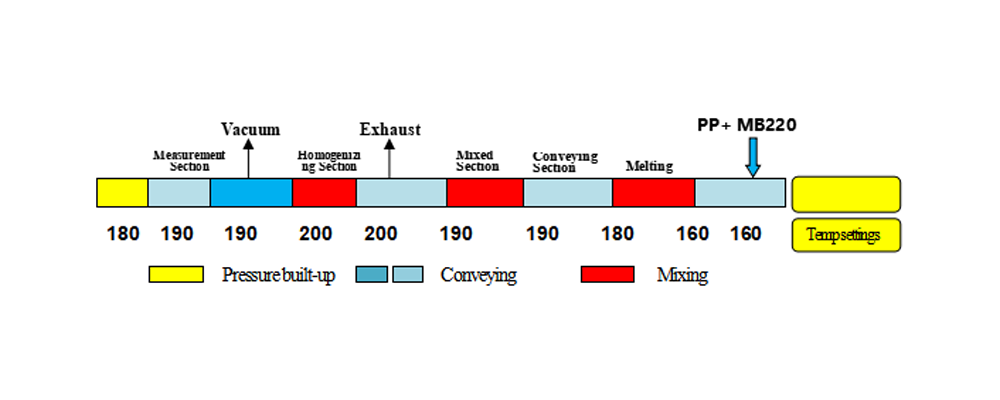

Model: Twin Screw Extruder 36

Extruding temperature of main machine(℃):160 160 180 190 190 200 200 190 190 180

Rotation speed of main machine: 300rpm

EXTRUSIOIN PROCESS: (Twin Screw Extruder)

3, MAIN PROPERTIES:

PROPERTIES | TEST METHODS | FORMULA A | FORMULA B | FORMULA C | FORMULA D | |

ASTM D792 | g/cm3 | 1.09 | 1.18 | 1.27 | 1.06 | |

MELT INDEX (230℃)/2.16kg) | ASTM D1238 | g/10min | 10 | 15 | 20 | 8.1 |

HDT(0.45MPa) | ASTM D648 | ℃ | 128 | 130 | 150 | 128 |

ASTM D638 | MPa | 28 | 30 | 40 | 27 | |

ASTM D638 | % | 32 | 29 | 27 | 55 | |

ASTM D790 | MPa | 42 | 54 | 58 | 41 | |

ASTM D790 | MPa | 3238 | 3450 | 3808 | 2600 | |

IZOD NOTCHED IMPACT STRENGTH | ASTM D256 | J/m | 26 | 30 | 80 | 21 |

FLAME RETARDANCY | UL94 | 1.5mm | V-0 | V-0 | V-0 | V-0 |

3.0mm | V-0 | V-0 | V-0 | V-0 | ||

GWIT | 3.0mm | 750℃ | 750℃ | 750℃ | 750℃ | |

GWFI | 3.0mm | 960℃ | 960℃ | 960℃ | 960℃ |

Note:

All the application data above are the typical data of MB220.